Biogas energy

In biogas plants, various types of biomass are used for the production of biogas. In order for its use to be economically justified, it must meet a number of conditions. Here are some of them:

- Relatively fast course of biodegradation – woody parts of plants, bones, feathers, etc. not suitable for use in biogas plants

- Significant biogas production

The distance between biomass and biogas plants should be optimal - Availability of substrate throughout the year or its possibility of storage

Only certain types of biomass can ferment on their own, many need a significant addition of substrates to sustain the process or balance the biochemical balance of the process. The right composition of substrates, developed by an experienced technologist, and in more complicated cases also based on specialized laboratory tests, determines stable and optimal biogas production and enables proper operation of biogas plants for many years.

Based on your data, including information about the type of substrate, its quantity, dry matter content and organic dry matter, our experts will develop a proposal for the optimal substrate composition for your biogas plant and determine the amount of biogas and energy that can be produced using them.

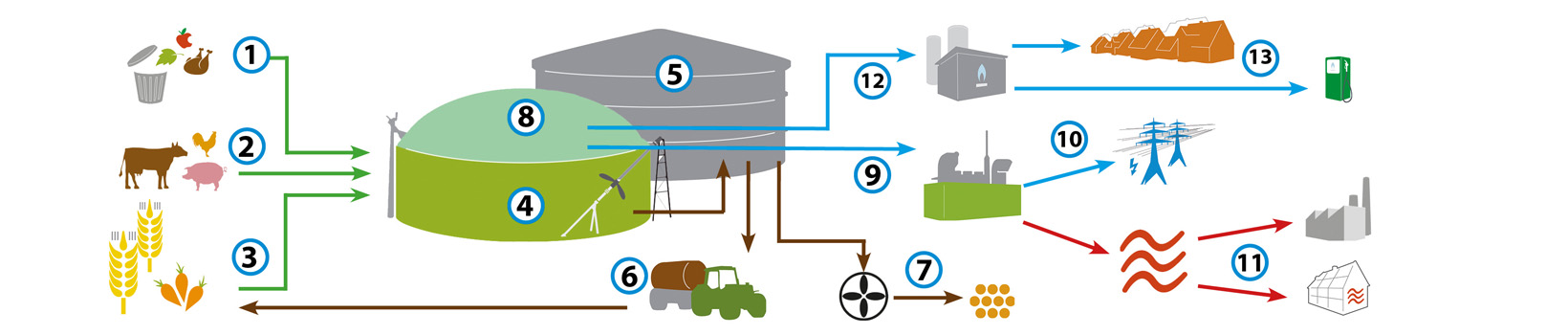

How does a biogas plant work?

2. Plant raw materials, e.g. maize, beets or grass, shall feed both animals – cows and pigs – and micro-organisms in biogas plants.

3. Slurry and manure shall also be used for the production of biogas.

4. In the fermenter with temperature approx. 38-40°C substrates deprived of light and oxygen are broken down by microorganisms. The end product of fermentation is biogas with methane as the main component. Biogas also contains corrosive hydrogen sulfide. The stainless steel fermenter has above all the advantage of being resistant to hydrogen sulfide and can be used for decades. In addition, it enables the operation of biogas plants in the thermophilic temperature range (up to 56°C).

5. The digestate substrate is pumped to the digestate storage, from where it is taken for further use.

6. Leftovers can be used as high-quality fertilizer. The advantage: Biogas slurry has a lower viscosity and penetrates the substrate faster. In addition, digestates often have a higher fertilizing value and are characterized by a less intense odor.

7. Drying and subsequent use in the form of dry manure are also involved.

8. The resulting biogas is stored in the roof of the tank

9. and burned in a block CHP plant to generate electricity and heat.

10. Electricity is transmitted directly to the electrical grid.

11. The resulting heat can be used to heat buildings or dry wood or crops.